Project Profile

Location

Gross Floor Area

Property Type

Number of Units

Project Summary

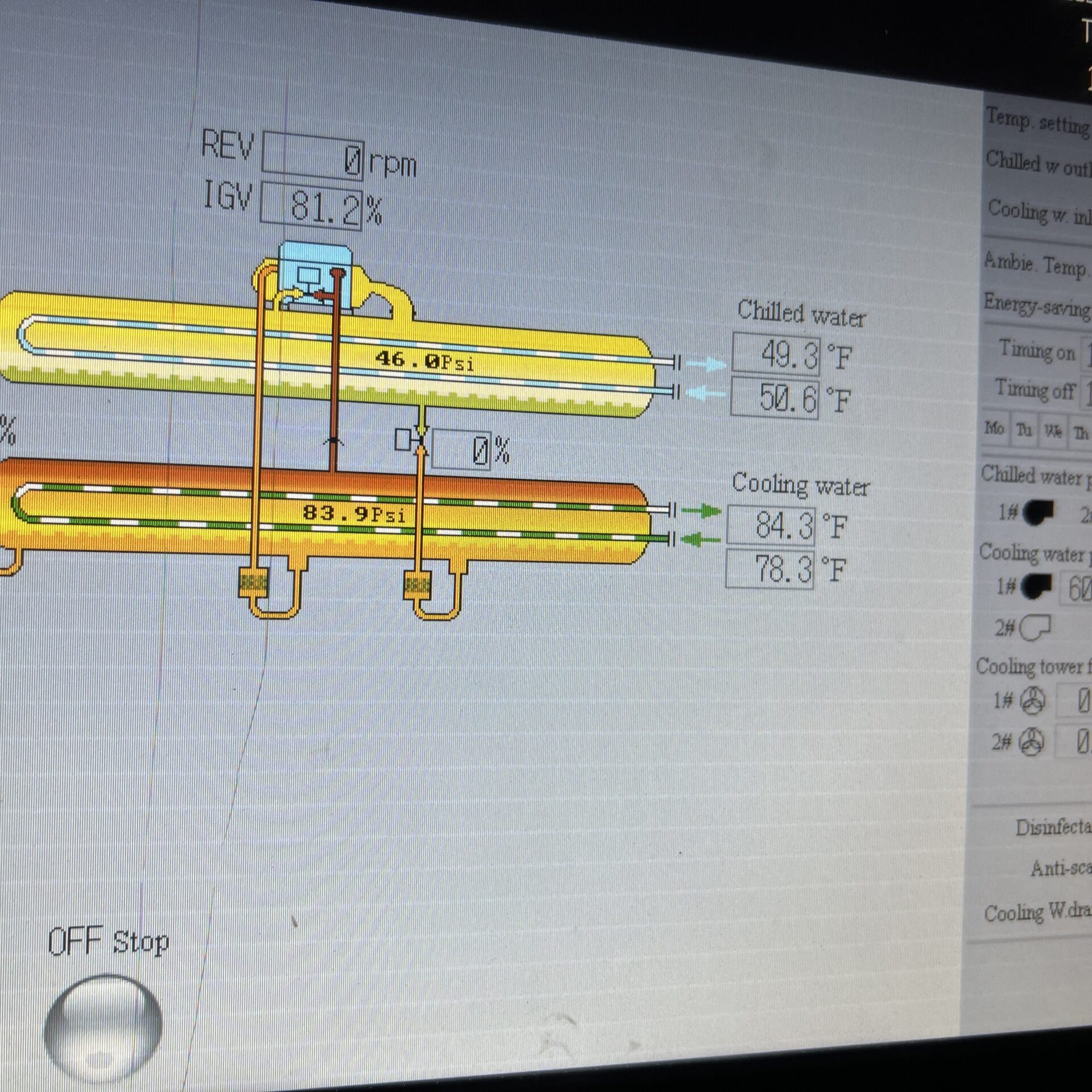

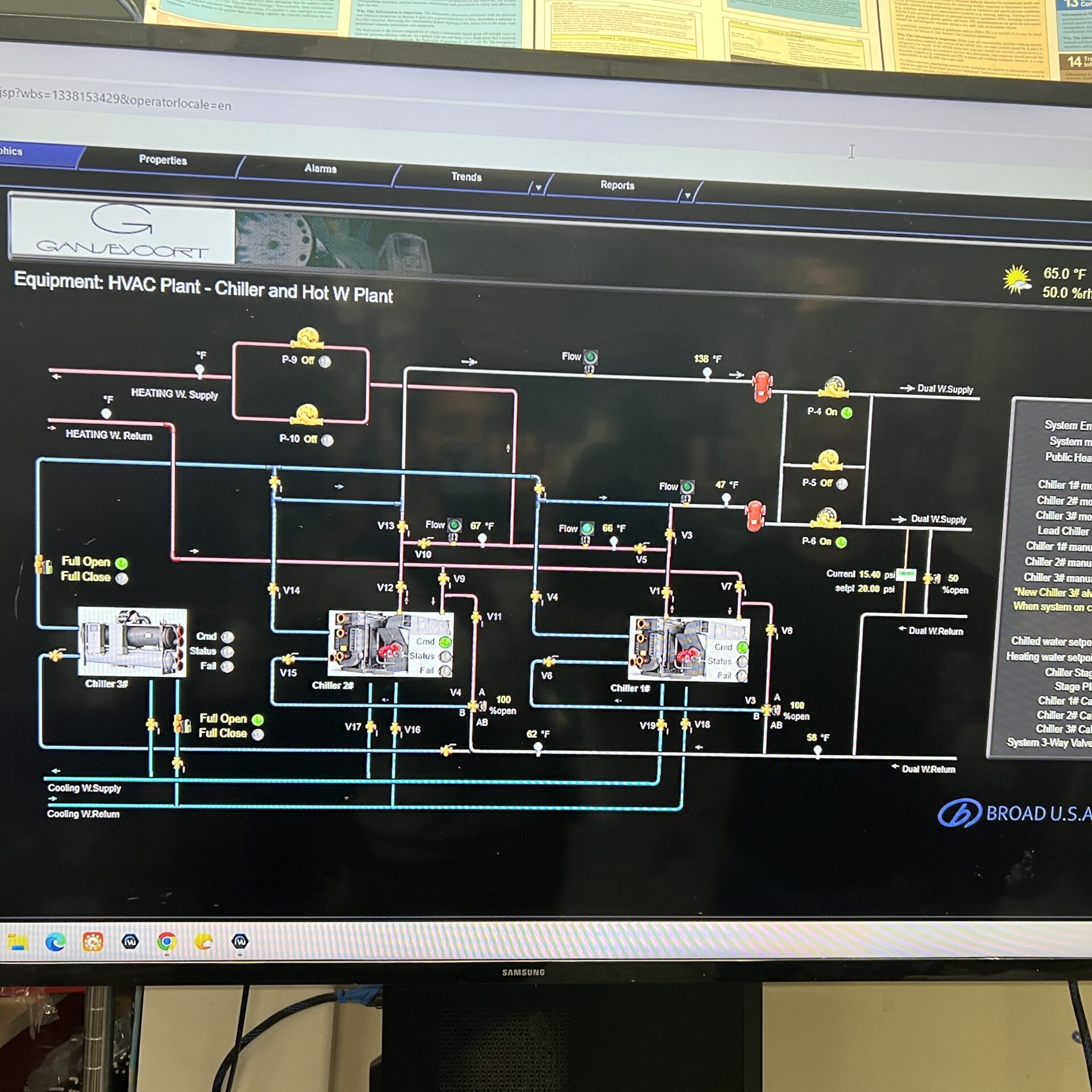

NY Building Systems Consultant Inc. (NYBSC) provided comprehensive MEP engineering, expediting, commissioning, and special inspection services. Working with Broad USA, NYBSC designed and implemented a high-efficiency Maglev electric chiller system (IPLV 0.35 kW/ton), replacing a 150-ton gas-fired absorption chiller and significantly reducing the building’s carbon footprint.

Project Description:

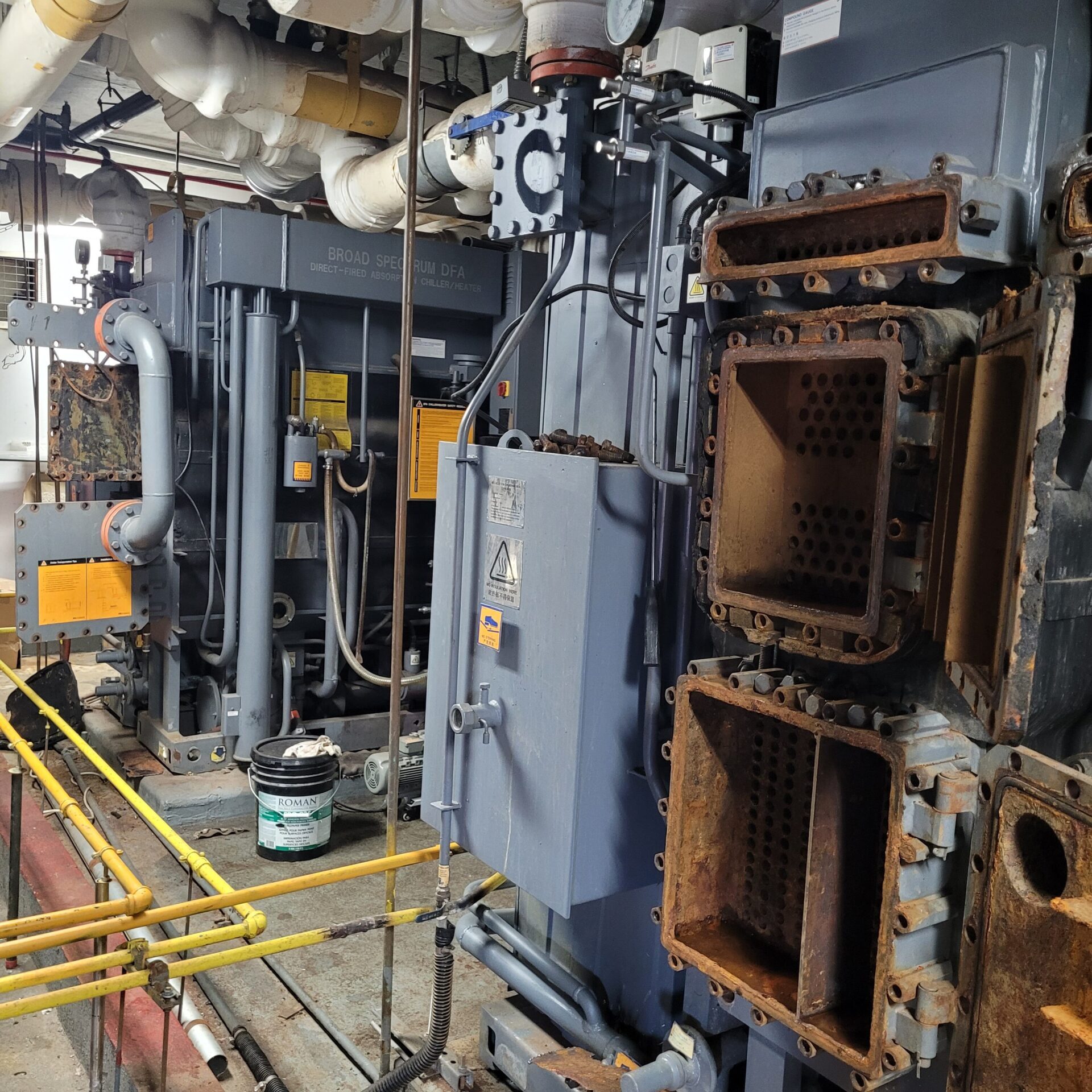

Gansevoort Meatpacking Hotel, a landmark luxury property in downtown Manhattan, upgraded its mechanical systems to meet NYC Local Law 97 by replacing an aging gas-fired absorption chiller with a high-efficiency electric chiller.

Scope of Work:

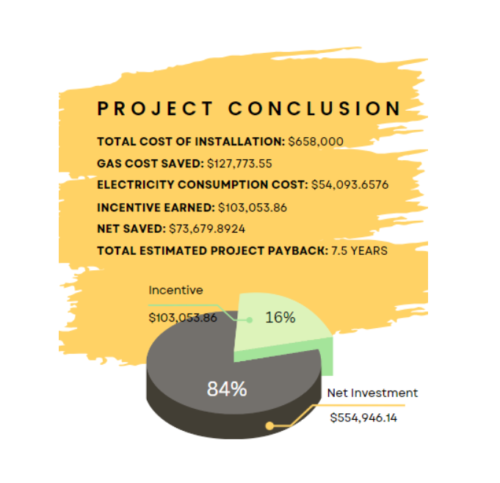

NYBSC provided comprehensive engineering design, expediting, commissioning, and special inspection services for the project. Working with Broad USA, NYBSC developed an electrification-focused design strategy to support NYC Local Law 97 carbon reduction goals. NYBSC’s team also performed energy savings calculations to support Con Edison incentive applications, along with detailed 3D modeling, load analysis, and energy simulations to optimize system performance.

Project Challenges and Innovative Solutions:

The chiller room’s location on the 12th floor eliminated the use of an exterior crane for equipment delivery. NYBSC addressed this constraint by coordinating with the manufacturer to implement a modular, site-assembled chiller solution, with all components engineered to fit within the building’s freight elevator and access limitations. This approach enabled efficient installation while maintaining uninterrupted hotel operations.

Environmental Impact:

The new system delivers approximately 354,513 kWh in annual energy savings and reduces 251 metric tons of CO₂ emissions—equivalent to removing 66 cars from the road or planting 300 acres of U.S. Forest . This also upgrades the Gansevoort as a model for sustainable hospitality operations in New York City.